Paint Curing Oven: Complete Industrial Guide for High-Performance Coating & Manufacturing Quality

GBM Is Pleased To Announce The Successful Dispatch Of One

Plot No. 145, Sector-16, HSIIDC Bahadurgarh, Haryana

Introduction

If there’s one piece of equipment in manufacturing industries that works quietly in the background yet forms the foundation of the entire production process, it’s the industrial oven. Whether it’s automobile components, powder coating, food processing, or pharmaceutical manufacturing—industrial ovens play a critical role across industries.

Industrial ovens are not just about providing heat. They improve material strength, remove moisture, cure coatings, and in many cases, determine the final quality of the product. Choose the wrong oven, and you’re looking at slower production, higher defect rates, and increased energy costs—plain and simple, a direct loss.

This article isn’t just about definitions. It’s a complete, practical guide designed to be genuinely valuable for manufacturers, plant managers, and decision-makers.

An industrial oven is a heavy-duty heating system designed for large-scale industrial processes. These ovens operate at high temperatures, can run for long hours, and are built to handle continuous production environments. Some people tend to compare them with the regular ovens used in homes—so for clarity, it’s important to understand that the two are fundamentally different.

The major differences between a household oven and an industrial oven include:

Industrial ovens are engineered to distribute heat uniformly, ensuring every part of the product receives equal thermal exposure and quality remains consistent. This is exactly why their use becomes unavoidable in manufacturing environments.

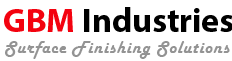

Industrial ovens are broadly classified into two main categories based on their operation and production flow: Batch Ovens and Continuous Ovens. Understanding this classification is crucial, because almost all industrial oven designs are developed around these two concepts.

Batch Industrial Ovens

Batch ovens are industrial ovens where multiple components or products are loaded together and processed through a fixed heating cycle. Once a batch is completed, the material is unloaded and the next batch begins.

The biggest strength of batch ovens is their flexibility. They can handle different shapes, sizes, and materials at the same time without requiring a permanently fixed production line. This makes batch ovens widely used in small to medium-scale manufacturing, job-work units, and customized production environments.

Key characteristics of batch ovens:

Continuous Industrial Ovens

Continuous ovens, as the name suggests, are designed for non-stop production environments. In these ovens, products move through the system in a continuous flow—usually via conveyor mechanisms.

These ovens are typically used in high-output manufacturing settings where speed, consistency, and automation are critical. Continuous ovens often integrate both heating and cooling systems, allowing products to exit the oven ready for the next stage of production.

Key characteristics of continuous ovens:

Batch vs Continuous Ovens: A Practical Perspective

In simple terms:

That’s why, when selecting an industrial oven, it’s not just about temperature or size. Understanding your production flow and output requirements is equally important.

Industrial ovens are used across almost every manufacturing sector. Let’s look at some real-world applications in major industries.

1. Automobile Industry

In automobile manufacturing, industrial ovens are used for:

Here, temperature consistency is extremely critical, because even a small variation can lead to component failure.

2. Food Processing Industry

In the food industry, industrial ovens are commonly used for:

Food-grade industrial ovens are designed according to strict hygiene standards, ensuring that food safety is never compromised.

3. Pharmaceutical Industry

In the pharmaceutical sector, the role of industrial ovens is highly sensitive and regulated. They are used for:

Ovens in this industry must comply with strict safety, validation, and regulatory standards.

4. Engineering & Fabrication Industry

In engineering and fabrication industries, industrial ovens are used for:

In these applications, industrial ovens significantly improve product life, performance, and long-term reliability.

As we discussed earlier, industrial ovens are broadly classified into two major types. However, different applications require different kinds of industrial ovens, and each type is designed for a specific use case.

As discussed earlier, batch industrial ovens are ovens where materials or components are loaded together in a single batch. Once a predefined heating cycle is completed, the entire batch is unloaded, and the next batch is then processed.

Batch ovens are designed to handle multiple components simultaneously—even if their sizes or shapes vary. This design makes them highly flexible and an ideal choice for customized or job-based manufacturing environments.

Key Features:

Best Suited For:

Batch oven = “load → process → unload → repeat”

These ovens are best suited for industries where every product is not identical.

Conveyor industrial ovens are, in fact, the most common and widely used form of continuous ovens—as discussed earlier in the continuous ovens section. It’s important to note that not all continuous ovens are conveyor ovens, but in manufacturing industries, the majority of continuous ovens are conveyor-based.

In conveyor ovens, the product travels through the oven on a moving conveyor belt, chain, or overhead system. Loading and unloading happen without stopping the process, which results in high production speed and consistent output.

These ovens are often part of fully automated manufacturing lines and, in many cases, incorporate cooling zones along with heating, so products exit the oven ready for the next stage of processing.

Key Features:

Best Suited For:

Conveyor oven = “the product keeps moving, the oven never stops”

That’s why conveyor ovens are unbeatable when it comes to mass production.

Tunnel industrial ovens are built as long, enclosed structures where products continuously enter from one end and exit fully processed from the opposite end. These ovens are typically part of continuous production systems and operate using conveyor-based mechanisms.

The biggest advantage of tunnel ovens is their multi-zone temperature control. Inside the oven, there are different heating zones—such as a pre-heating zone, a main heating zone, and sometimes even a cooling zone. This allows the product to receive gradual and controlled heat, significantly reducing the risk of thermal shock or defects.

Key Features:

Best Suited For:

Tunnel oven = the factory’s “highway”—the product never stops, it just keeps moving forward.

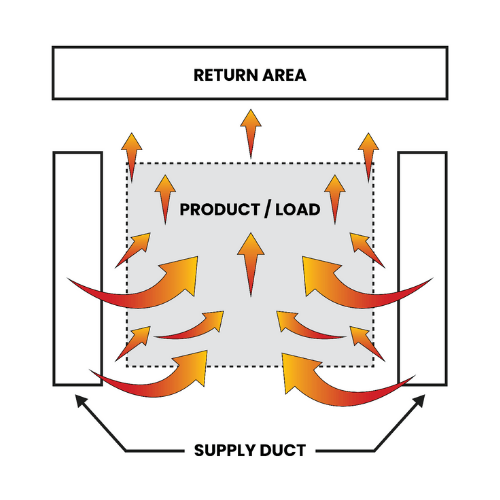

Drying ovens are primarily used for moisture removal—without damaging the material’s structure or overall quality. These ovens operate using a controlled combination of temperature and airflow, which ensures uniform and predictable drying.

Airflow design plays a critical role in drying ovens. Hot air circulation is engineered in a way that allows moisture to escape efficiently, ensuring that not only the surface but also the internal layers of the material dry properly. This is why drying ovens are widely used in paint and chemical processing applications.

Major Applications:

Why Drying Ovens Matter:

A drying oven doesn’t just provide “hot air”—it functions as a controlled evaporation system.

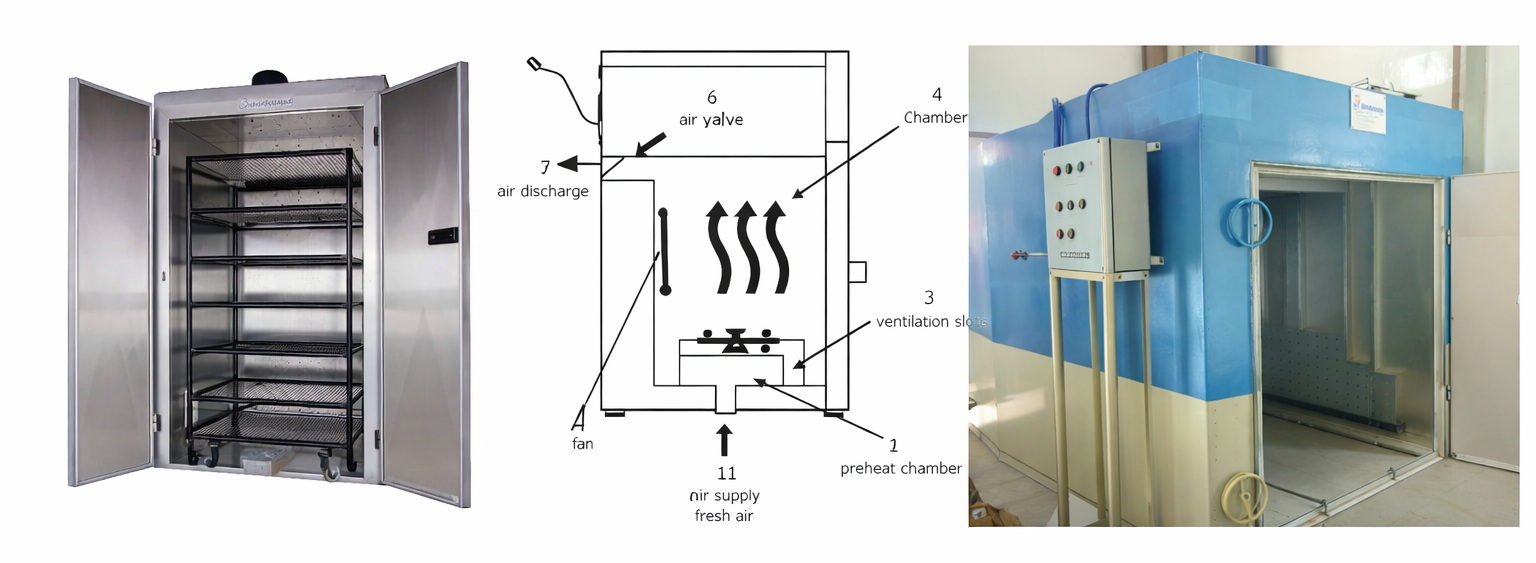

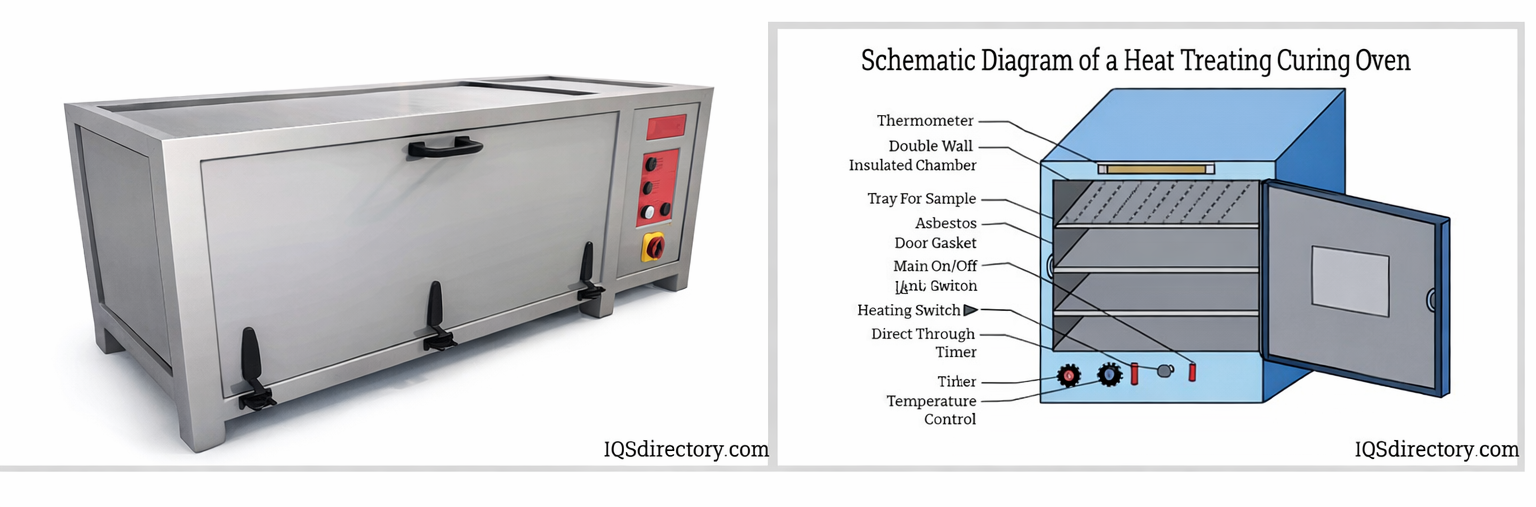

Baking and curing ovens are used in coating, varnish, resin, and powder coating processes where simple drying is not sufficient. These applications require chemical bonding and molecular-level curing, which is not possible without precise temperature control.

In curing ovens, the temperature profile is carefully engineered to ensure proper cross-linking of the coating, even surface distribution, and long-term durability. Through this process, the coating doesn’t just sit on the surface—it becomes an integral part of the base material.

Key Benefits:

Typical Industries:

Drying = removing moisture

Curing = permanently setting the coating

The working principle of an industrial oven may appear simple at first glance, but the internal system is highly advanced and precisely engineered. Industrial ovens operate on different energy sources—such as gas, electricity, steam, hot water, microwaves, or fuel oil—depending on the application and temperature requirements. Each component has a clearly defined role to ensure uniform heating, process consistency, and reliable product quality.

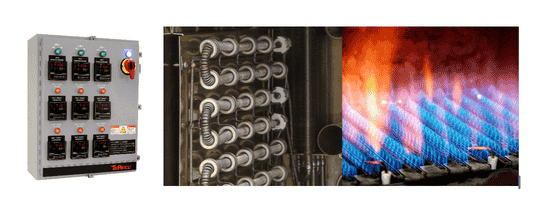

1. Heating System

In industrial ovens, heat is generated using multiple energy sources. Common systems include electric heaters, gas burners, steam coils, hot water systems, and microwave heating. The heating system produces the required temperature and controls heat input according to the process needs. Gas-fired systems are widely used for high-temperature and continuous applications, while electric heating is preferred where precise temperature control is critical.

2. Air Circulation

Powerful fans and blowers circulate hot air evenly throughout the oven chamber. This circulation system ensures that heat reaches every component uniformly, eliminating cold spots and the risk of uneven heating. Proper airflow is essential for consistent product quality and repeatable results.

3. Temperature Control

Modern industrial ovens use digital PID controllers and temperature sensors to monitor temperature in real time. These controllers automatically adjust the heating system, maintaining accurate and stable temperatures—especially important for processes such as curing, baking, and heat treatment.

4. Insulation

High-quality thermal insulation minimizes heat loss inside the oven and significantly improves energy efficiency. Good insulation not only reduces power consumption but also helps maintain a stable internal temperature throughout the process.

5. Safety Features

Industrial ovens are equipped with multiple safety mechanisms, including:

These safety features ensure safe operation and protect both the equipment and operators in case of any abnormal condition.

Now that you understand the types of industrial ovens, their working principles, and applications, the most important question arises—which industrial oven is right for your business?

This is not a short-term decision. An industrial oven usually remains a core part of production for many years, which is why clarity and foresight are essential during the selection process.

My recommendation is simple: instead of making a decision based only on a specification sheet, first understand your actual production requirements.

When selecting an industrial oven, focus on the following factors:

Industry experience makes one thing clear: selecting the wrong industrial oven leads to higher operating costs, increased defects, and slower production.

That’s why it’s always better to work with a manufacturer who understands your process and recommends the right solution—rather than simply selling a product.

While buying an industrial oven, I’ve repeatedly seen a few common mistakes being made across the industry. If you can avoid these, you’re already a step ahead.

The most common mistakes buyers make include:

It’s important to understand that an industrial oven is not an expense, but a long-term investment.

The right oven improves productivity, reduces rejection rates, and makes production predictable—while the wrong oven simply adds problems to your operation.

After understanding the types of industrial ovens, their working principles, and the key selection criteria, one question naturally arises—which manufacturer can truly understand your real manufacturing needs?

Based on industry experience, one name that can be confidently recommended is GBM Industries.

GBM Industries is counted among India’s leading manufacturers of industrial ovens and surface-finishing solutions. The company is ISO 9001:2015 certified and designs and supplies high-performance equipment for both domestic and global industrial clients. GBM Industries is not just a machine manufacturer—it is a process-driven industrial solutions provider.

My recommendation is not based on branding or claims alone, but on GBM Industries’ practical product range and engineering-driven approach.

The industrial ovens manufactured by GBM Industries cover exactly the categories we’ve discussed in detail throughout this article:

In simple terms:

Engineering-Driven, Not Catalog-Driven

One of the strongest aspects of GBM Industries is that their solutions don’t start with a catalog—they start with the process.

While designing every industrial oven, GBM Industries seriously evaluates the following factors:

This approach delivers direct benefits to clients—stable performance, lower operating costs, and consistent product quality.

Built for Long-Term Industrial Use

GBM industrial ovens are:

This is why GBM Industries’ solutions are widely trusted across automotive, powder coating, electrical, foundry, fabrication, and heavy manufacturing sectors.

If you consider an industrial oven not just as a machine, but as the core system that defines your production quality and efficiency, then selecting the right manufacturer should never involve compromise.

F.A.Q s

Industrial ovens typically operate between 100°C and 500°C or even higher, depending on the application.

Yes, modern industrial ovens are highly energy efficient, thanks to advanced insulation and smart temperature controllers.

Batch ovens are designed for discrete loads, while conveyor ovens are used for continuous production processes.

Conclusion

Industrial ovens are the silent heroes of manufacturing industries. They improve product quality, maintain production consistency, and make industrial processes reliable. Whether it’s heat treatment, drying, or curing, choosing the right industrial oven is essential for long-term success.

When you select an industrial oven based on your application, production requirements, and future scalability, you not only save on operational costs but also significantly improve product quality and customer satisfaction.

GBM Is Pleased To Announce The Successful Dispatch Of One

GBM Is Pleased To Announce The Successful Dispatch Of One

GBM Is Pleased To Announce The Successful Dispatch Of One