Paint Curing Oven: Complete Industrial Guide for High-Performance Coating & Manufacturing Quality

GBM Is Pleased To Announce The Successful Dispatch Of One

Plot No. 145, Sector-16, HSIIDC Bahadurgarh, Haryana

Introduction

In modern manufacturing, paint and coating are not just about appearance — they are about performance, protection, and product life. A perfectly applied paint layer means nothing if it is not cured correctly. (Curing simply means heating the painted part in a controlled way so the paint fully sets and becomes strong, not just dry on the surface.) This is where a Paint Curing Oven becomes one of the most important pieces of equipment in any surface-finishing setup.

If you are new to industrial ovens or want a clear overall understanding before going deeper into paint curing ovens, our team has already put together a detailed guide on “Industrial Ovens: Uses, Types, Working Principle & Complete Buying Guide.”

It explains the fundamentals in a simple, practical way and is worth reading to get the full picture before choosing any industrial oven solution.

A paint curing oven uses controlled temperature and time to lock the coating firmly onto the material. This ensures the paint does not peel, crack, fade, or fail during real-world use. In simple terms, curing turns fresh paint into a durable, long-lasting protective layer. From automotive components to industrial machinery, appliances, metal furniture, and fabricated structures — curing ovens decide whether a product will survive years of use or start failing too early.

For consistent quality, low rework, and durable coatings, the right paint curing oven is a production necessity that directly affects quality, rejection rates, and operating costs.

A Paint Curing Oven is an industrial heating system designed to cure liquid paint, powder coating, varnish, enamel, or specialized industrial coatings by applying controlled heat for a specific time duration.

Unlike simple drying, curing involves:

The oven maintains precise temperature, airflow, and dwell time, ensuring the coating reaches its optimal physical and chemical properties.

In short:

Drying removes moisture.

Curing creates strength.

Industrial ovens are used across almost every manufacturing sector. Let’s look at some real-world applications in major industries.

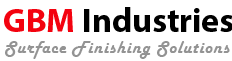

The working principle of a paint curing oven follows a controlled thermal process:

1. Loading of Painted Components

Painted parts are placed inside the oven using trays, trolleys, racks, or conveyor systems depending on the oven type.

2. Controlled Heat Generation

Heat is generated using:

3. Uniform Air Circulation

High-efficiency circulation fans distribute hot air evenly throughout the chamber. This avoids hot spots and ensures uniform curing across all surfaces.

4. Temperature Holding (Soaking Phase)

The oven holds parts at a specified temperature (typically 120°C – 220°C) for a defined time to complete chemical curing.

5. Cooling & Unloading

After curing, components are cooled naturally or using controlled ventilation before unloading.

This precise sequence ensures repeatable quality, minimal defects, and optimal coating strength.

| Aspect | Drying Oven | Paint Curing Oven |

|---|---|---|

| Purpose | Moisture removal | Chemical bonding |

| Temperature | Low to medium | Medium to high |

| Result | Surface dry | Fully hardened coating |

| Durability | Limited | Long-term protection |

| Industrial Use | Pre-process | Final finishing stage |

1. Batch Paint Curing Ovens

Best for low-to-medium production volumes.

2. Conveyorized Curing Ovens

Designed for continuous production lines.

3. Powder Coating Curing Ovens

Specifically designed for powder coatings.

4. Infrared / Hybrid Curing Ovens

Used for fast curing cycles.

GBM Industries designs and manufactures custom curing oven solutions tailored to production volume, coating type, and floor layout.

The working principle of an industrial oven may appear simple at first glance, but the internal system is highly advanced and precisely engineered. Industrial ovens operate on different energy sources—such as gas, electricity, steam, hot water, microwaves, or fuel oil—depending on the application and temperature requirements. Each component has a clearly defined role to ensure uniform heating, process consistency, and reliable product quality.

Ensures chip resistance, corrosion protection, and premium finish.

Metal Fabrication & Structural Components

Improves weather resistance and surface hardness.

Electrical & Appliance Manufacturing

Provides uniform color and scratch resistance.

Heavy Engineering & Industrial Machinery

Extends service life under harsh conditions.

1. Superior Coating Strength

Cured coatings resist peeling, cracking, and fading.

2. Long-Term Corrosion Protection

Heat-cured paint seals metal surfaces completely.

3. Production Consistency

Every batch meets the same quality standard.

4. Reduced Rework & Rejection

Lower defects mean lower production costs.

5. Faster Production Cycles

Optimized curing time improves throughput.

Paint curing ovens typically operate between:

Advanced ovens include:

GBM Industries integrates precision control systems to maintain stable curing cycles even under continuous operation.

Modern paint curing ovens are engineered for:

This results in:

Energy-efficient curing ovens directly improve manufacturing profitability.

Selecting the wrong oven can increase defects and costs. Key factors to consider:

✔ Coating Type

Liquid paint, powder coating, varnish, or enamel.

✔ Production Volume

Batch vs continuous operation.

✔ Component Size & Weight

Determines chamber size and loading system.

✔ Heat Source Availability

Electric, gas, or dual-fuel.

✔ Floor Space & Layout

Customized design ensures optimal workflow.

GBM Industries works closely with clients to design application-specific curing ovens rather than generic solutions.

GBM Industries is among India’s trusted manufacturers of industrial ovens and surface-finishing solutions, offering:

From small batch ovens to large conveyorized curing systems, GBM Industries delivers reliable, scalable, and performance-driven solutions for diverse industries.

F.A.Q s

Yes. Powder coating requires precise heat to melt and chemically bond the powder.

With proper design and controls, yes — but customization is recommended.

Batch ovens are designed for discrete loads, while conveyor ovens are used for continuous production processes.

Batch ovens are designed for discrete loads, while conveyor ovens are used for continuous production processes.

Absolutely. Incorrect time or temperature leads to weak or brittle coatings.

A paint curing oven is not just a heating chamber — it is the quality gate of industrial coating. The right curing solution ensures durability, consistency, and customer satisfaction while reducing waste and operational cost.

For manufacturers aiming to deliver premium-grade, long-lasting coated products, a professionally designed paint curing oven is a smart investment — and with GBM Industries, it becomes a long-term production advantage.

GBM Is Pleased To Announce The Successful Dispatch Of One

GBM Is Pleased To Announce The Successful Dispatch Of One

GBM Is Pleased To Announce The Successful Dispatch Of One